Sustainable Manufacturing Practices: Reducing Carbon Footprint in Auto Production

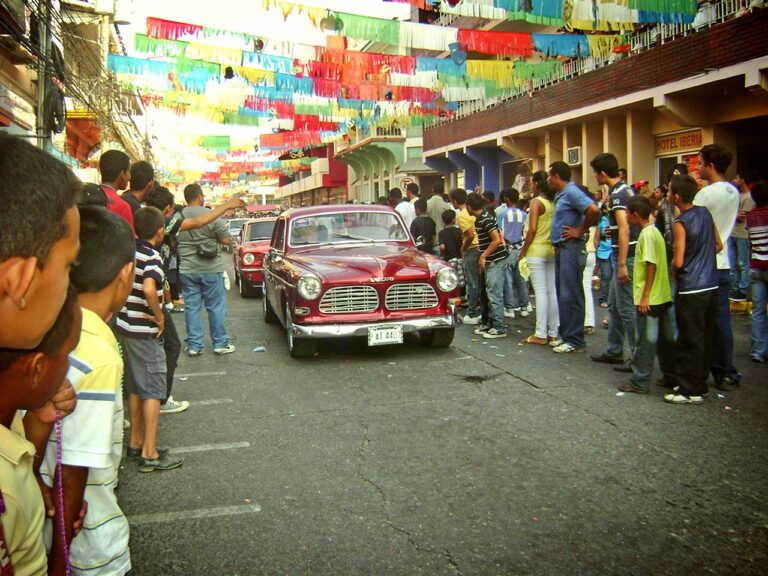

The automotive industry faces a multitude of challenges in production processes. One significant obstacle is the growing complexity of modern vehicles, with advanced technologies and features requiring intricate assembly procedures. Ensuring the seamless integration of these components while maintaining efficiency and quality standards poses a constant challenge for manufacturers. Additionally, the demand for customization and personalization in vehicles has added layers of complexity to production lines, resulting in longer lead times and higher production costs. Finding a balance between mass production and customization remains a key challenge for the auto industry.

Another pressing challenge in auto production is the need for sustainable practices throughout the manufacturing process. As environmental concerns continue to gain prominence, automakers are under pressure to reduce waste, energy consumption, and emissions associated with production. Implementing eco-friendly initiatives such as recycling, using renewable materials, and reducing carbon footprint are essential for meeting regulatory requirements and consumer expectations. Balancing environmental stewardship with operational efficiency and cost-effectiveness presents a critical challenge for auto manufacturers seeking to maintain competitiveness in a rapidly evolving industry.

Implementing Renewable Energy Sources

Renewable energy sources have emerged as a crucial focus for industries striving towards sustainability. In the automotive sector, the integration of renewable energy can significantly reduce greenhouse gas emissions and environmental impact associated with manufacturing processes. By harnessing solar, wind, or hydroelectric power, automakers have the opportunity to enhance their environmental credentials and contribute positively to global efforts in combating climate change.

However, the implementation of renewable energy sources in auto production is not without its challenges. One key obstacle lies in the significant upfront investment required to transition from conventional energy sources to renewable alternatives. The high costs associated with infrastructure upgrades and technology adoption can deter some manufacturers from fully committing to renewable energy solutions. Consistent policy support and financial incentives are essential to encourage greater adoption of renewable energy sources within the automotive industry.

• Transitioning to renewable energy sources can reduce greenhouse gas emissions in the automotive sector

• Solar, wind, and hydroelectric power offer sustainable alternatives for manufacturing processes

• Automakers can improve their environmental credentials by integrating renewable energy solutions

Despite the challenges of upfront investment, there are clear benefits to be gained from implementing renewable energy sources in auto production. The long-term cost savings and environmental advantages make it a worthwhile endeavor for manufacturers looking to enhance their sustainability practices. With advancements in technology and increasing global awareness of climate change issues, the automotive industry is gradually shifting towards a more eco-friendly approach.

• Long-term cost savings can outweigh initial investment costs

• Increasing global awareness drives demand for sustainable practices in auto production

• Technology advancements make integration of renewable energy sources more feasible

To fully realize the potential of renewable energy sources in the automotive sector, collaboration between governments, industry stakeholders, and consumers is crucial. Policy frameworks that support clean energy initiatives and provide incentives for businesses to invest in sustainable practices play a vital role in driving this transition. Additionally, consumer demand for environmentally friendly products will further motivate automakers to prioritize renewable energy solutions in their operations.

• Collaboration among governments, industry stakeholders, and consumers is essential

• Policy frameworks supporting clean energy initiatives are key drivers of transition

• Consumer demand for environmentally friendly products encourages adoption of renewables

Optimizing Supply Chain for Sustainability

Sustainability in the supply chain is a critical goal for companies looking to reduce their environmental impact. One key challenge is understanding the full scope of emissions produced throughout the entire supply chain, from sourcing raw materials to final product delivery. Companies are increasingly investing in data tracking and reporting tools to gain visibility into their supply chain operations and identify areas for improvement.

Implementing sustainable practices in the supply chain also involves working closely with suppliers to integrate sustainability criteria into their operations. Building strong partnerships with suppliers who share the same commitment to sustainability is essential for driving meaningful change. This collaboration can lead to innovations in product design, packaging, transportation, and waste management, all of which contribute to a more sustainable supply chain ecosystem.

What are some key challenges in auto production when it comes to sustainability?

Some key challenges in auto production include reducing carbon emissions, minimizing waste generation, and ensuring ethical sourcing of materials.

How can renewable energy sources be implemented in the auto production supply chain?

Renewable energy sources such as solar and wind power can be implemented in the auto production supply chain by investing in on-site renewable energy generation, purchasing renewable energy credits, or partnering with renewable energy providers.

How can the supply chain be optimized for sustainability in auto production?

The supply chain can be optimized for sustainability in auto production by using data analytics to identify areas for improvement, collaborating with suppliers to implement sustainable practices, and implementing green logistics strategies such as route optimization and modal shift.